Thursday 17th - Continuing preparations and an extra bit

Another day with more major shunting in the lengthy process of putting back our three rakes as we would like them, plus a host of other activities in preparation for the new season.

Apologies for fewer photos today but 5042 kept me busy.

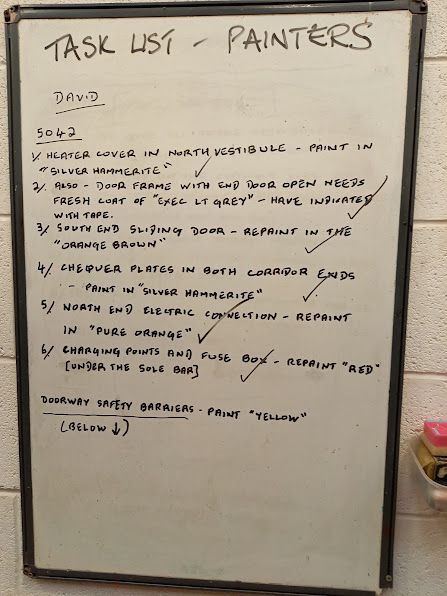

Firstly, the Paintshop whiteboard with the list of jobs written up last thing on Tuesday for David on Wednesday. Almost all involved TSO 5042 and all were completed, bar the extra job with the safety barriers. David was joined by Jeff who had swapped his day to Wednesday.

Continuing with 5042, with the corner demarcation tapes removed, Martin began by painting the gloss black up to the edge of the chocolate and cream. He then went on to add more orange to the electrical connections, and then painted the lamp brackets.

One of the major outstanding jobs with 5042 was to clean up the insides of the window frames, which were pretty grubby and tarnished to say the least. Roger, from our Indoor Gang, cleans up the table for this bay after completing the window frame cleaning. The formica on the wall sides also needed a good clean and Roger sorted this out as well.

Bob K. and I were also involved. The other aspect of the windows was to ensure that the sliders were free and worked. After the painting, it is inevitable that most will be stuck, but a long screw driver inserted between each set soon loosens them. After that it was some frantic sliding back and forth to ease their movement and for toning up the arms! Roger then applied copper ease to the tracks and hopefully all the sliders should now be working fine. They will be checked again before the coach goes back out.

All the door backs needed more coats of varnish. Bob did the Cotswold side and I followed with the Malvern side.

With the compartments done, the next to have the window cleaning treatment was the large north vestibule and toilet compartment, with both Roger and I involved here too. Bob S. later joined us to paint some fresh silver Hammerite on the air vent grills and toilet compartment heater cover.

Bob's first job was to carry on with the paint repairs to the catering doors on RBr 1672. Still some more to do on these and the surrounding exterior panelling, but they are looking much better now.

Inside the kitchen area the installation of the two new water heaters continues, involving both Richard I and Phil.

With the shunting completed Alex continued the internal renumbering of doors and windows. The one big change in the rake is of course the replacement of BSK 35308 with newly refurbished BSKD 34929, and there's nothing more annoying than bird droppings on the new paint!

There are still some minor things to do in 34929's compartments such as putting back the seat numbers. All the shunting to some extent prevented Alan, Geoff, Paul and Dennis continuing their internal rake preparations. I'm afraid my efforts in 5042 meant that I missed them too.

Another of Alex's jobs during the day was to highlight the new replica works plates for the Queen Mary brake van and Mink A van.

Richard was back in to create the door lintels for the Mink A van. These have been primed ready for undercoating.

*************************************

An extra bit from Alex when he was recently at Toddington

*************************************

Comments

Post a Comment