Thursday 17th/Saturday 19th - Buckeyes, an Elk, and loads more

A busy two days where a relatively dry spell of weather was very welcome, especially for the jobs needing to be done outside. And being another Thursday/Saturday posting, with a Wednesday evening interlude, it's another lengthy one. Gathering photos for the blog is quite a job in itself and I feel very much now like a roving reporter. This is especially so on a busy day and if intending to cover as many of the activities as possible. Over 50 photos were taken on Saturday, from which I made the final selection for that day.

Thursday

The big job for Thursday was the annual buckeye examination for the Maroon Rake (Rake 2). The rake had been brought down from Toddington last week and now had to be split up to allow access to the buckeye couplers. This is a lengthy operation in itself with plenty of scotches required once the coaches are separated, with the exception of the brake coach of course. The following group of photos of the activity were taken both by Nick and myself.

[Photo : Nick] The rake is moved back a considerable distance because when spilt the seven coaches extend quite some way.

[Photo : Nick] The line beyond the road bridge with the cutting extending to Greet Tunnel.

[Photo : Nick] At the limit the first coach is uncoupled and scotches put underneath. The train is then pulled back, and the next couch uncoupled and made safe.

[Photo : Nick] And so on, and so on until the rake is completely split up. Spare chocs, painted yellow to make them stand out, lie on the platform edge.

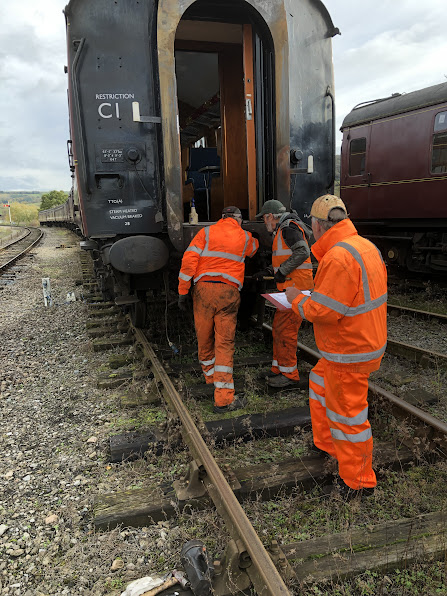

By the time I came out to see the work the Maintenance Gang were well into the job.

A close-up of the group, with Gerry and Nick taking a break from metalworking and learning the job so as to assist Stu, John, and a third member of the Maintenance Gang. John as Head of the gang is doing the record keeping.

Later on a view of the team from the other platform. As I took the photo I heard Stu state "pass" for the particular parameter check that he was doing.

[Photo : Nick] A close up of one of the buckeyes.

[Photo : Nick] Job almost completed and the rake is being reassembled. Ian was driving the 03 with Andy and Tony as shunters.

[Photo : Nick] Andy signing the calling back.

[Photo : Nick] The reassembled rake is now in the headshunt and out of the way of the events this coming weekend. The south end buckeye is now checked - the final one! Well done team.

********************************

On now to other activities.

With the buckeye exams going on, time to do some more shunting. The LMS guards van and conflat are being returned to the Works siding. So what went into the Barn?

Wow, what a monster! It looked big when outside, but in the confines of the Barn, the ELK looks even bigger and takes up almost all of the jack road. It's in basically for an FTR (fit to run) examination.

We usually have both main running rakes at Winchcombe for the closed season in January and February, but having the Maroon Rake handy now is a chance to get some early maintenance and repairs done. Alan and Roger repair a window slider where the catch had gone missing.

In the guards compartment of BSKD 34929 there was the sound of drilling. It turned out to be Richard II wiring up so as to be able to fit a tracker. This very useful device will enable the train to be located by our operations staff should there be a problem or stoppage between stations.

On my way back to the works, I was just in time to see Paul emptying water out of one of the lights in the north vestibule in TSO 5023, the final coach in the Maroon Rake. No doubt a roof cowl letting in water after all that heavy rain. Some Flexacryl should sort this out when we can get access to the roof.

While on Platform 2 I went to have a look at the tree that Jane Bennett had planted in memory of Peter. Let's hope it eventually blooms as beautifully as the photograph on the label. It will really stand out amongst the traditional Great Western pines.

Looking up at the Workshop roof, it is a pleasure to see the planks that Pam and I painted during the recent gala are now covering the first of the old leaking skylights.

On to CK 16221 and in the Workshop Phil B. is finishing off the tracks for the compartment doors. One of the originals had a torn scrtew hole, so a replacement was taken from our store and cleaned up. They are now on board 16221 awaiting fitting.

Dave was cleaning compartment heating control knobs.

As it was Thursday we had a clearer run of the interior, and for Bob K. this meant exclusive access at the south end of the coach. As such our varnishing maestro achieved a considerable amount of work, beginning with a light sand with mainly 240 paper.

The more he adds, the better it looks.

The whole of the south vestibule and the outer wall up to second class inner door, from where I was taking the photo, were coated. It's looking brilliant but we will still be adding more. The compartment walls certainly need more.

With painting now almost finished, for a while we can get on to other jobs, before exterior varnishing. Phil J. working his way along the Malvern side cleaned the outsides of the windows.

Jeff was doing the inside. I think he managed to get the south end ones done before Bob got around to varnishing that part.

The next job was continuing the lengthy clean up of the tarnished and dirty window frames. Wire wool is excellent for this. So is very fine sandpaper - 240 and 320 grades do a great job.

Another job now in progress is reinstating the luggage racks. Actually, just the light bulbs and seat cushion to go back in and the south side of this first class compartment will be finished.

The luggage rack in the next compartment, in place but only half secured. We have had to cut longer pieces of the threaded rod to enable the connection between the racks on either side of the compartment dividing wall, and some of the holes bored through don't line up perfectly so some adjustments are needed.

All the kitchen doors in RBr 1675 will be having aluminium backs. Ainsley trial fits the first of the new back panels cut out from the aluminium sheets that arrived last week.

On Wednesday David A. assisted Pat with the cleaning of the guards corridor in BSK 35308. This in turn has enabled Pat to crack on with the repainting in the same Executive Light Grey gloss and the north end of the corridor is now looking very much better.

*****************************

Now a brief interlude from Alex

Wednesday evening

I'll just squeeze a Wednesday evening update in here as I missed hijacking Nick's posting, so for those who don't follow our new wagons Facebook page:

*****************************

Saturday

A somewhat mad day at Winchcombe with so many other activities going on and two very large marquees erected in the station car park ready for the Santa Specials. Parking at the site was overflowing in the extreme. Besides us and PWay (both having high attendance), there were all the staff involved with Santa Specials and the final packing of Santa presents.

Beginning with the former London Transport ELK (rail/sleeper carrier), Andy Th. begins undoing the draw gear.

Another view of this colossal vehicle which must be something like 70 feet in length.

It was door fitting day for the Vanfit.

Robert gives me a cheery wave, while Paul waits for Richard to assist with the lift so as to mark the position of the hinges.

With the positions marked, Robert has cut out the recesses for the back part of the hinges.

The locations are spot on and the hinges can now be bolted on.

Returning later to find the left door now mounted, and Paul and Richard trial fitting the right side ready for marking up the hinge positions.

Mid afternoon and the doors are fully mounted. Locking bars to fit and a complete paint to finish the job.

On the other side of the van, Maurice continued the cleaning up using a powered brush on the underframe.

The Dirty Gang were also working underneath the south end of RBr 1675. The buckeye coupler was first removed.

After which the object of the work for Ian and Andy Tu. was to remove the draw gear.

The rebuild of the kitchen doors from 1675 continues, with Ben and Ainsley discussing the next steps for this particular one.

A further visit to the Woodwork/Doors shop and the new aluminium panel had been mounted.

And the next one with Ainsley carefully measuring where to make the cutout for the door lock.

Success! The special attachment for the bandsaw fits perfectly. It was specially made by John S. on the milling machine from a new aluminium bar and will greatly assist when cutting straight edges.

Although the guards corridor is not fully repainted in BSK 35308, the decision to have a go at the corrosion on the guards door and adjacent panel was a good one considerning the lovely weather. Pat removes the worst of the old flaking filler.

A good session with wire brush and sandpaper to remove much of the rust and then a coating of red oxide. Later on, with the latter now dry, Pat begins applying the filler. This was sanded down and then to protect it from the threatened rain the next day, undercoat Madder was painted on. More filler will be needed, and then more undercoat and finally top coat Maroon to complete it. It will be sometime before 35308 comes in for a much needed refurb, but this will help to prevent this area getting worse.

A car problem prevented Pam coming in on Tuesday, but she made up for the lost time. The Woodwork Shop sign was started and the first coat completed.

Although it meant a late finish the Changing Room sign had a second coating and is now the first of the six signs completed and ready for hanging.

Getting ready for the 1100 morning break, but whatever is Paul doing laying these out?

As can be imagined, CK 16221 is having a lot of attention, especially on Saturdays. Ian and Andy Tu. assist the Upholstery team with the loading of the heavy first class seating.

In one of the compartments Jenny and John fit one of the side panels.

The loading continues with Steve also lending a hand. Moving these heavy seats is quite tricky in the confines of the corridor and even worse when getting them into the compartments, with careful tilting needed to get through the doorway.

Laura checks that this side panel is firmly secured.

In this compartment the luggage rack is up, lighting units and heating control fitted, and seating almost finished. Once the heating unit on the floor has been checked, the seat cushion can go in and this side is finished. With the opposite side similarly finished, the compartment door can be reinstated and we're done.

Ah, not quite done! I had forgotten the compartment tables, one of which is having a thorough clean by Dave E.

A trial fitting of a seat side panel in one of the second class compartments.

After lunch Dave H., Kevin and myself extracted the seating from storage for two of the three second class compartments.

The two access cupboard doors in the north vestibule are being replaced. Simon carefully trims the plyboard to the same size as the top one.

With the recesses cut out he adds the hinges.

Hmm, not seen one of these neat little machines before. Steve carefully cuts out the recess for the cupboard door lock.

With the door completed, he mounts it in the vestibule.

The first is now in place, with the second going on.

The south vestibule plumbing is being assembled.

The varnished toilet shelves are now receiving their metal edge bands.

The completed shelves awaiting fitting.

Phil cuts out some supports for the toilets.

The emergency window has been a trial to say the least. BR gave up with them after the leakage problems experienced - I hope we don't have the same problem!

One very happy Ben with the window problem now sorted out. For the first time it shuts perfectly.

At the north end of 16221 Ken is completing the mounting of the communication cord equipment.

The completed unit on the left side of the corridor connection.

So, what's going on here then? Well rumour has it (via a text from Alex to me on Whatsapp) that the charter freight will soon be passing by. The PWay gang have similarly downed tools to watch it go by.

With orange clad Michael leaning out of the back the train is slowly propelled by.

Ah, there he is! Looking after the Guards/TTI roster certainly has its perks as you can have the pick of the plum jobs.

After a run through the station and on to the tunnel for more photos, the charter behind 4270, the perfect choice for the job, returns to Toddington.

With absolutely perfect autumn weather the charter organiser and group must be well pleased it had all gone so well. We certainly enjoyed seeing the train go by.

More excellent work again! I'm not a fan of the wooden scotch as they can (and do) fall out, these are much better: https://www.petebriddon.co.uk/products.html and no, I'm not related to Pete!

ReplyDeleteMany years ago when I was Guard training I went with the rest of the class to Oxley Sidings to do buckeye training, as we didn't have any at Kidderminster, and it was required training. Heavy aren't they? The class tutor showed us just exactly how easy running a mark three coach is when the brakes are released. One person can push it along, and he did!!, totally failing to see the scotch near the wheels which they rode up and he very nearly had the thing 'off the road'!! Luckily, the whell set ran back down the scotch and returned to its starting possition. Whew!! We ribbed him about that later. Never saw an Elk though from that day till this.

ReplyDeleteThe van fit looks great. What is next? Maybe the Monster?

Regards, Paul.

A very fine and informative blog....thank you.

ReplyDelete