The Wagon RestorationTeam basically comprises two members, Richard S. and Paul E, with other members of Carriage & Wagon becoming involved as various aspects of the work become available.

In the past all manner of vehicles have passed through the Works. Examples are the GWR Horse Box, Shell tanker, MICA van, Barry van, LNWR van, Shocvans, Minks, Mogos, China Clay wagon, Dogfish ballast wagons, Conflat, Fruit C van, Toads, Queen Mary, BR Guards van, Monster van, CCTs, Ferry van, Tool vans, GUV, PMV - the list goes on and on, and overall it is quite a range and all providing a lot of interest.

So over to Richard as he describes the general background to the team and covers the rebuild of the China Clay wagon.

***********************************************************************************

I have tried to offer some insight into how we do a restoration as

well as team dynamics and all with a sense of humour. Here goes....

Given

our department is called Carriage & Wagon it still seems to

surprise some people that as well as restoring the heritage carriage

fleet, so our customers can enjoy steam and diesel train rides in our

beautiful Cotswold country, we also restore wagons. After all, our

railways led the industrial revolution by using wagons to transport all

types of goods from coal, milk, fish, vegetables to beer, watercress and

bananas. Any child's model train set included a few wagons to change a

toy into a layout. We, as a railway, are fortunate in that we have a

good fleet of wagons; a few have been restored to provide the basis of a

freight train and the rest wait silently on side roads to be worked on

when time, funds and opportunity present themselves.

The

Wagon restoration team is by nature a fluid one and expands and

contracts depending on what is to be done. Paul and I tend to

work as the principal team given the two main construction elements of

metal frames and timber planks or panels. Paul has a background in

electrical engineering and so can advise on all things metal and

mechanical. I scraped an O level in woodwork and maintain a good

working relationship with the Head of the Woodwork shop! Skills

crossover is encouraged and Paul can sometimes be found with a saw or

paintbrush and myself with a spanner or drill. Thankfully, wagons are

much simpler in construction than carriages being essentially a metal

chassis holding the wheels and brakes, a skeleton frame above and wooden

planks and doors.

To introduce our work here

is a photo gallery starting with a wagon that has missing and damaged

planking/floor, rusting metalwork and a non operating brake system. I

have chosen the China Clay wagon as not only is there the wagon to

restore but also the cover hood to produce.

Our method for restoration if described in a 'Delia' recipe book would be...

Firstly, take lots of photographs and measurements...too many is much better than trying to guess later!

Take the wagon and remove all wood to leave the metal work revealed.

Remove

all rust to bare metal, repair as necessary, prime, undercoat and

topcoat to prevent rusting. This includes sole bars, all metal

framework, axles, wheels, buffer beams.

Remove

and clean brake components, check vacuum cylinder and replace as

necessary, check all hoses, free off all moving parts and

lubricate...more photos in situ before taking any thing off helps.

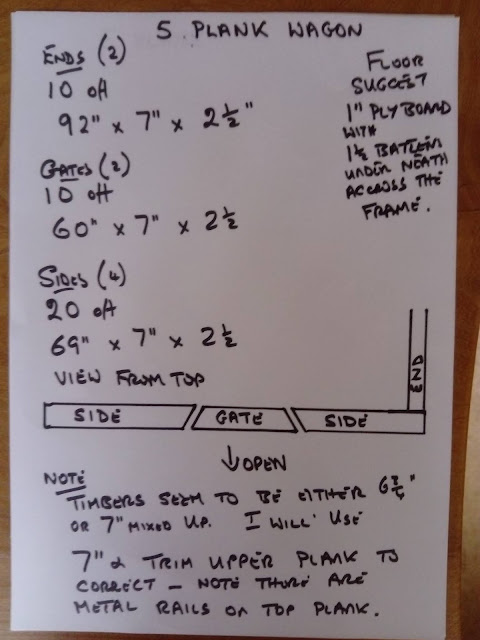

Cut

timber to size and trial fit. Prime, undercoat, gloss with as much

paint as the Head of the Paintshop will allow you to use [as much as you need - Dave Clark]. Purists will

note we use gloss paints although I am hopeful that I may be able to use

a more matt finish in future restorations...in their original

construction, especially in the 'austerity post war years' paint was

only applied to visible surfaces and so inner beams and pipes were

exposed to rust. To try to add extra protection we try to paint all

surfaces that can be accessed.

Fit the new floor

with ply sheets and assemble the planks, repeat for the hatch doors and

fit back the canvas hood frame. Sign write with number and, at the

request of the Upholstery team, paint 'Return to Fowey' where such

wagons were an everyday sight and have long discussions regarding the

canvas hood. Should it be a single sheet as original or perhaps, given

we want to use the wagon to dry store timber planks, a boy scout tent

canvas with ends that can be accessed? We decide to try a tent design!

The design is covered by the Head of Upholstery who produces a 'cad'

(computer aided drawing) to replace the previous crayon on paper

sketch.

Await delivery of the 'tent' and then 'rope in' other interested helpers to fit and 'rope on'!

I think that might be enough and hopefully the pictures tell the rest of the story.

Richard S.

************************************

***********************************************************************************

Thank you Richard for a very comprehensive overview of the team, its work, and putting together the excellent set of photos.

A simply terrific blog. You chaps are just wonders in what you do for wagon restoration.

ReplyDeleteAlex is a really professional sign writer.

ReplyDeleteI miss the sound of loose coupled unfitted goods trains passing. They have a wonderful sound all their own, also when being shunted.

ReplyDeleteGreat blog.

Regards, Paul.

Another wonderful wagon restored so well , i often wonder how they got the china clay out of the gate , a shovel perhaps ? As i have said before , all these restorations should be promoted and seen in the magazines and on social media to highlight your good efforts over many months . john M.

ReplyDelete