Woodworking in Carriage and Wagon

Continuing our series of special articles on the work of Carriage & Wagon, this one by Steven Barnfield and Eddie Paddon (respectively the current and former heads of the section) covers all the various aspects of woodworking done for both the Department and indeed for many other parts of the Railway.

All the photos are by Dave Clark and the late Peter Bennett, except where indicated.

*************************

How we used to be - the original Workshop

The first woodwork facility within C&W was under the Mezzanine floor in the original Goods Shed, which the team also helped erect and produced the timber stair case and decking. In this area we were able to incorporate a work bench and a couple of second hand wood machines underneath. ln time we were able to expand the area and had another work bench for doors so that we could have a devoted door team specialising in the repair and replacement of Carriage doors.

Eddie Paddon, former Head of the Team, in the old Woodwork area

The Woodwork area specially rearranged for the 2012 Carriage & Wagon Open Weekend

It all changed in 2014 - the new Woodshop

In 2014, thanks to the Bill Ellesmere Extension to the C&W workshops, we were able to establish a self-contained functioning "Woodshop" so there was no contamination to/from other trades. We were able to obtain additional second hand wood machines to suit our needs.

[Photo : Steven Barnfield] A montage of our current machines

Additional work benches were also

produced for the Door Team to suit their particular needs. The following show these being made by some of our former team members.

As the Upholstery Dept also now had a new workroom as part of the extension we made them some benches, again to suit their particular needs.

One of the two large tables. Note the cutouts in the top cross piece to support the metal poles for rolls of moquette

Our extensive range of products

To give some idea of what the wood team are now able to do in the restoration of the carriages. Whilst the external structure of a BR Mk1 carriage is steel, with variations to suit the type of vehicle, the majority of the internal fit and finish is all in timber. Where possible original components are restored and reused. When this is not possible we are now able to produce replacements for the vast majority of components in the appropriate material, e.g. hardwood, softwood, veneer, etc, in house. These components include window frames, doors and door frames (both internal and external), seating, tables, etc.

A display set up by Steven for the 2022 Cotswold Festival of Steam

Floors, ceilings and internal panelling are replaced where necessary

in the appropriate finish. A range of veneered plywood, eg. Sapele,

Oak, Formica etc, can be sourced to replace panelling that has been

damaged beyond reuse.

New veneer panel with cutouts and beading on the south vestibule end wall in CK 16221 - note the reflections in the multi-coated varnish

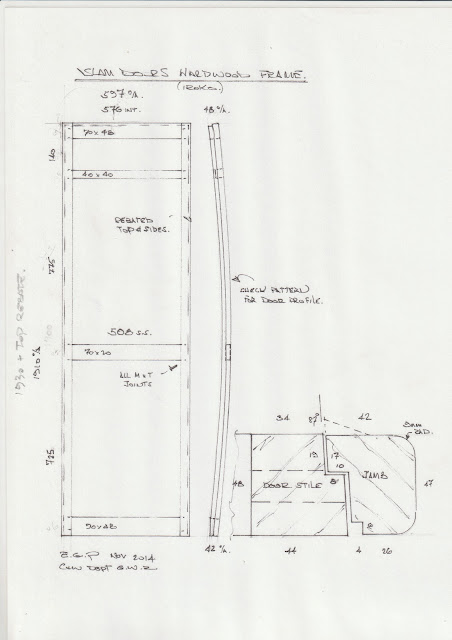

An example of our efforts is the exterior slam door to the carriages. These were originally mortise and tenon jointed oak frames with a steel outer skin. When it has been necessary to replace these frames we have used iroko hardwood for its cost and structural flexibility. The frames are appropriately profiled with closing edge rebates.

Mk1 hardwood door frame diagram (Eddie Paddon))

Once the outer metal skin is added the interior drop window mechanism is fitted plus a door latch and hinge plates. The internal hardwood trims and panels (usually mahogany or similar) having been profiled, etc, can be fitted

Mk1 hardwood door components diagram (Eddie Paddon)

Mk1 hardwood door frame

A different type of door. A new wood frame for one of the quarter doors used for the three catering entrances on RBr 1675 that require a greater width than the standard doorway, hence in effect these entrances are double-doored. The quarter door width is actually about a third of that for a standard door.

A collection of door pulls with Richard working on the next one

Robert making the parts for a new door panel

Bonding the parts together

[Photo : Steven Barnfield] A completed and working door on CK 16221

In later times all the external doors were cast in aluminium which has needed a different approach for fitting the internal wooden trims and panels. Generally the aluminium doors had steel screws to attach the various functioning parts and wood backing. Overtime the steel and aluminium bonded making the steel screws very difficult to remove. As such the solution used by British Rail and, since then by us, is to have wood inserts to which all the parts can be attached.

Of course all doors are profiled as the carriage body side. Any idea what that radius might be? Well it's 28 ft and 1 3/16 inches" or 8.5374 metres.

Carriage Windows

[Photo : Steven Barnfield] Window frame components

Part of a new window frame in CK 16221

A miscellany of carriage items

Part of the support structure for the end vestibules in coaches

Colin repairing a compartment sliding door with Eddie sharing a joke!

Simon fitting new veneer panels in the south vestibule in CK 16221

Eddie cutting new tops for corridor heating pipes

General repairs and rebuilding

The Woodwork team also take on general repair work to operational coaches and the internal rebuilding of coach interiors during major refurbishments. To an extent this work is shared with the Indoor Gang, who do general repair work in the coaches within our 3rd and 4th Rakes.

Fitting the upper support for the heavy corridor sliding door

Refitting compartment sliding doors

Fitting replacement doors for vestibule access cupboards in CK 16221

Special projects

As well as producing and refitting the components general to most of the coaches the woodwork team have also been involved in designing and producing other specialised fittings and adaptations where appropriate to each carriage. These have included catering service counters: -

[Photo :Roger Bush] The serving counter in the DMU centre car

and disabled facilities: -

The disabled area in TSO 4614 showing in particular the double doors that were specially fitted in the wide entrance and the new side panelling and shelves

The construction of the disabled compartment in BSKD 34929 using oak, including the veneer panelling

Currently the team are involved with refitting the RBr 1675 to better serve the requirements of the catering team. Keep an eye on the blog for progress with this long-term project.

Wagons

In addition to all this work on the carriages the woodwork team are also involved in a wide range of work on the various wagons on the railway. Work involved with these includes replacing framework, planking on sides and roof, flooring, manufacturing replacement doors etc.

The important initial assessment prior to any rebuild

Two of the four new doors made for the Mink A 124589 rebuild in 2022

Two of the four new doors fitted to the BR Vanfit 774445

Robert is finishing off a new footboard for the "Cheltenham High Street" Toad brake van

Wood sections prepared by Robert for the rebuild of the roof and upper sections of the end cabin walls in the "Cheltenham High Street" Toad brake van

Fitting out the Discovery Coach at Winchcombe

Finally the coach was handed over to the project group for adding the exhibits, with the Woodwork team providing more help with items such as display cases and cut-out shapes representing woodland, etc, for the map.

Des Adams, one of the project team, working on the map of the line.

The final result prior to the setting up of the internal display screens and exhibits

Broadway Station

Building the counter and back shelving. It was transported to Broadway using the Baguley-Drewry railcar and trailer.

Arrival at Broadway and initial installation

Keith undercoats new safety barriers that are used to secure open doorways during coach refurbishment where doors have been removed

For many years the Woodshop had a mascot in the form of "Ria", Eddie's much loved Labrador who he would bring in on his Saturday morning turns

Hopefully this gives you a flavour of some of the wide variety of woodwork tasks the team undertakes across the Railway.

.jpg)

Excellent blog post. I spy a Wadkin PK saw in the pictures, lucky fellows.

ReplyDeleteThe Wadkin saw was retrieved by Eddie from a local farmers barn. He had the intention to sell it for scrap so we gave him £300 and got the late Stevie Warren and his JCB to collect it and trundle round the lanes to our yard. It was thick with rust so Maurice duly set too to restore it. With a very deep service by our engineer she is as good as new.

DeleteA simply superb blog. You chaps and some ladies work wonders for the GWSR..well done is an understatement.

ReplyDeleteA wonderful blog and worthy of keeping for easy access.

ReplyDeleteRegards, Paul.

Amazing insight into the vast amount and variety of work done. I tried to enter the railway name on Smile Amazon today but couldn't find it, could you put it in a future blog and as a reminder in future blogs.

ReplyDeleteDuring lockdown Eddie Patton made at home the new signing in desk for the "The Goods Shed" new building at Toddington. He was always happy to oblige, as are all the other C&W team

ReplyDeleteLooked at it again.. A blog and a half..thank you.

ReplyDeleteA brilliant blog as always, thankyou Dave. The work produced by you and the team is absolutely top drawer.

ReplyDelete