Tuesday 22nd - A very mixed bag

It was tempting to call this "More lines", following Alex's Saturday posting, but "A very mixed bag" would be a better description. We certainly had a good number attending with staff more associated with Thursdays and Saturdays coming in to complete outstanding jobs.

The arm exercise today was partaken by Ainsley and myself with the delivery of 35 pieces of plyboard (for doors, walls and floors) and hardboard (for ceilings). Steve will be sorting it all out on Saturday.

Moving on now to the timed projects, although the season start has now been pushed back a week, we still have to get everything ready by our own planned deadlines.

Progress in RBr 1672 is good with respect to the fitting of the two new water heaters. Richard I is installing a new socket. The first heater has been temporarily removed.

Bryan, from our Metalwork team, is sorting out a backplate for the second heater.

Up on the Workshop mezzanine where the Electrical team's bench is located, Richard II shows frustation as to why, despite all his testing, the buzzer on the new equipment fails to work. This is the small black cylinder in the top section, which sounds when the heaters have reached the required temperature. Knowing Richard, he will get this sorted out.

The other timely project being worked on today is of course TSO 5042 and completing the lining out. Maurice tapes up the remaining lines on the Cotswold side needing black gloss. When he had finished this he painted the fittings for the north end door (handles, stops and droplight top bar).

On the Malvern side Roger tapes up the lower line for gloss black. The wire is suspended from the gutter and is very convenient for hanging the roll. When doing the upper lines the tape can be propped up in the gutter, as shown in the previous photo.

Richard also worked on the Malvern side and, unable to locate the yellow tape we use for lining out, tried the green tape that we acquired from our supplier (sent in lieue of the normal white general purpose tape). To everyone's surprise and delight it proved to be as good as the yellow, so a very good fallback if necessary.

With 5042 it's now into the very last stages with window cleaning, paint snagging and a few other minor jobs left to do. The coach will be shunted back out on Saturday.

On now to the current restoration project with CK 16221. This door is having a complete new set of back panels, door pull and base, all of which will look lovely with 2-3 coats of varnish.

Moving to the second bench, Ainsley is attaching the finger pull on this door.

Cleaning up of the sliding compartment doors continues with Tony working on the droplight runners.

Plenty of noise with Dave sanding down one of the maintenance cupboard doors and Tony now doing the main sanding down of his door.

More varnishing by Keith of items from 16221.

Two more chairs from RBr 1675 have been stripped by the Upholstery team and, having been given a light sand by Keith, are being given the first coat of varnish. Note the new underseat panel and, if you look closely, it can be seen that in fact the panel is in two sections - the reason for this is described below.

In Upholstery, another stripped chair awaits the fitting of the underseat panel.

A large piece of hardboard has been cut into the relevant sized portions for the underseat panels. The template sits on one of these. The line drawn across the template marks the fold point, necessary originally so that the template could be fitted underneath, the chair legs and crossbars making access difficult. The fold point in turn marks where about a quarter of each portion has to be cut off for the same reason.

Dave is preparing more of the small sections.

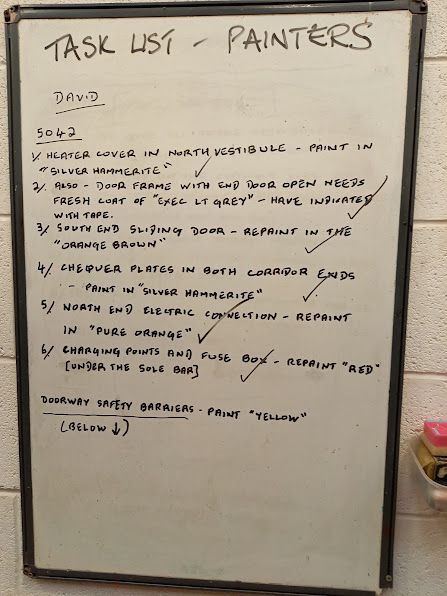

Finally some progress with the new door safety barriers, now being painted in an initial coating of yellow. A second coat will go on and then some black stripes. As previously explained, these will be fitted in a coach doorway where the door is missing, but not being used for access, and will prevent the possibility of someone falling out. The barriers are locked in using the small revolving attachments.