Saturday 4th - A very busy day

A bumper attendance with 27 in during the day, several arriving later having attended the annual Guards/TTIs seminar. As you will see from the sheer number of photos it was a very busy day with so many different things going on.

Winter shutdown maintenance continues with Paul and Dennis working along the Main Rake. Paul vacuums the north vestibule of FO 3132 "Mary", collecting up all the bits from my efforts to remove the adhesive from the toilet door that displayed a "Not in use" notice. Unfortunately a fresh notice has to go on as the toilet chute is missing (another job on that very long list).

It was then back to external cleaning.

The Mogo gang, Paul and Maurice, taking a well earned break.

Having had enough of struggling around the pile of PWay material inside the Mogo (it was becoming a hazard and there has even been a recent mention in the Comments about it), Paul and Maurice got cracking and began unloading the many items.

Just loose bits and rubbish left to clear up, but what a difference and so much better for the remaining rebuild.

[Photo : Paul E.]

Alex, back from the Guards/TTIs seminar, applies grease to this hinge bolt and replaces the nut.

Back to the job in hand with Maurice painting the south end base plate with dark grey undercoat.

Returning to the start of the day, Robert and Ben discuss the build of the replacement side doors for the Mogo.

More checking of the notes and measurements before the build.

The first door taking shape. The first of the large tailgate doors is underneath.

While I was in the Woodwork shop Robert pointed out the superb chisel rack that Alan S., the newest member of the Wood Team, has made. A brilliant job!

Following my initial 5 minutes "just have to have a go" dig at the cracking paint and filler on FK 13326, after it had been shunted into the Paintshop on Thursday, George got going properly on what will be a lengthy job to get the coach into a fit state for rust treatment, refilling and repainting.

Knowing that the coach will be in for a while, John and Jenny begin inspecting the state of the seating. Some of the armrests are worn and if particularly bad will be recovered in a black moquette, which should look fine - we have no spare Charcoal Check for repairs.

Laura jumps up onto the seat to inspect the luggage rack netting. John appeared at that moment with a tray full of the rack hooks needed to replace any missing ones.

Pam was at last satisfied with the fire bucket repainting, so it was great to be able to return them to the station. A small blob of Blu Tack was placed on top of each hook to prevent the handles being scratched.

On to the next job, the sign for our Changing Room. Alex had made out the template so Pam got cracking and soon had the French Chalk letters displayed ready for painting on the pre-varnished board.

Another nicely done sign in its first coat of paint. A second coat of cream paint, a black shadow and another two coats of varnish and this will be ready to replace the paper sign currently displayed.

Alex painted the frame of the Toddington Station notice board in Dark Stone. It is now ready for signwriting.

Meanwhile two notice boards from the museum coach at Toddington have been brought down and Alex begins lettering the first.

The picture frames made by David D. for the first class compartments in CK 16221, completed and ready for varnishing.

What would we do without Kevin? Since he has been our storekeeper everything is so much easier to find, sorted tidily, and if freshly painted, as was done with the table legs (below) that weren't required for 16221, covered in clingfilm to protect the paint. The storage locations list on our lobby notice board is invaluable and frequently consulted.

With the FK now in the Paintshop and requiring some serious sanding, varnishing the compartment doors from TK 24006 may come to a temporary halt for a while. However there will be other jobs arising from 24006. Dave is cleaning one of the door handles that had become somewhat tarnished.

Soft wire wool and the very fine 240 grade sandpaper work wonders.

Some replacement pipework from under one of our Main Rake coaches was being made by John.

Quite a contrast between the old and new, the latter with neatly cut threads.

The completed assembly ready to be installed.

Phil was repairing one of our vices.

In the Barn our Main Rake brake coach TSO 9000 is undergoing a lot of effort on the doors and doorframes. With just over 3 weeks of the shutdown period left, we have to keep the momentum going and get this coach back into shape. Phil works on the Malvern side central doorframe adding filler where required.

Jeff undoes the securing straps on the Cotswold side south door which will allow it to be fully opened.

Ben then came to do some Door Team work which involved removing the striker plate and redrilling the securing holes so that better screws could be inserted. Jeff meanwhile moved to the Cotswold side centre door and worked on that frame.

Jeff later returned to the original door to continue his work. I finished my day by going round the three doorways with a pad sander to continue the cleaning up of old paint and sanding the new filler where applied. More filler will be required on all three before we can start painting.

Ainsley works on the striker plate on the Malvern side south doorway.

Lots of noise emanating from inside RBr 1675 and on investigating it turned out to be Simon trimming the base of this partition to allow the wood floor support to be installed.

Outside the coach Alan is now positioning the support where needed.

Alan and Simon now install the edge sections.

The north end corridor connection for 1675 is now in the Barn to allow more space for Ken to prepare it for mounting.

A novel way to temporarily seal off pipework from under 1675.

At the south end the drawbar apparatus was being removed by Tony and Stuart.

This was to enable magnetic particle testing to check for surface and near-surface flaws and the detection of internal cracks.

Later on I captured Tony releasing the north end drawgear.

Stuart inspects the first part.

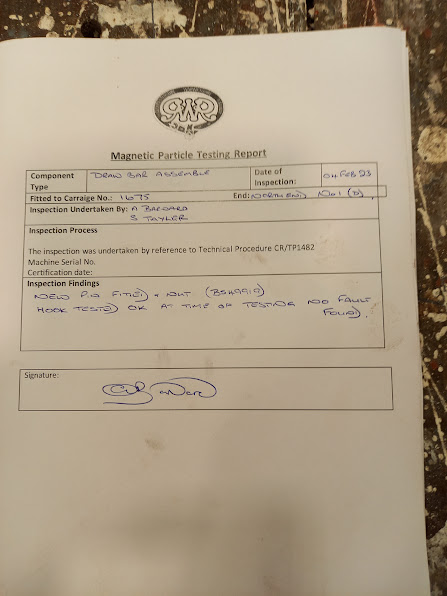

One of the completed report forms for the special testing.

It was a hive of activity again on the Barn jack road. This was related to the exchange of axleboxes and general refurbishment work to prepare a new south end bogie for CK 16221.

One bad axlebox had already been removed, the problem there having been the difficulty in the extraction of the internal part (Andy did tell me what this was called and I thought I had noted it on my phone).

The north bogie will be the one that will be placed under one of our permanently static vehicles.

The bad axlebox indicated with a red cross.

The south bogie undergoes preparation of a new life under 16221.

With the work completed the duff bogie is wheeled out and connected to the 03.

The good one follows, is secured to the other ..................

................ and the pair pulled out and onto another track.

CK 16221 is then brought in and by the end of the day the bogie exchange had been completed.

With nearly all the dirty Gang present Ian thought it would be good to have a group photo. So from left to right: Andy Tu., Stuart, Ian (HOD), Andy Th., Richard (PLC Chairman and Company Secretary), John, and Tony. Missing are Clive (Deputy HOD and also Rolling Stock Director) and Bob (Tony's son).

Comments

Post a Comment